Trafotech SEALED BREATHING SYSTEM- the easiest way to get rid of frequent maintenance of Silica-gel

Breathers and keep transformers dry

RANGE

Series A: For transformers 16 KVA to 400 KVA /// Series M: For transformers 500 KVA to 500 MVA

Normally, transformers are provided with Silica-gel breathers to protect them from atmospheric moisture. In fact, Silica-gel

breathers, in their best form also, are in-capable to fully protect transformers from moisture. This is called Free-breathing

system, which does not fully protect transformer from outside moisture.

And unfortunately, breathers generally do not remain in their best form due to lack of frequent maintenance they require,

thereby further de-grading their performance as a moisture protector device. This creates a huge revenue loss happening due

to ingress of moisture to transformer solid insulation and oil, reducing their life to half or even lesser. Presence of moisture in

solid insulation accelerates its ageing process and pre-mature end of transformer takes place.

IMPORTANT: Life of liquid insulation is reversible, but life of solid insulation is irreversible. Generally, life of transformer = life of

insulation.

The pre-mature death of a transformer not only causes loss of equipment but the outage generally creates more production

loss than the cost of transformer.

Many complicated breathing systems have been tried but none succeeded 100%. Some of them failed due to technical

inferiority and others, due to high cost.

Salient features of Sealed Breathing Systems invented by Trafotech

a. Efficiently protect the transformers from moisture & keep transformers dry

Provide 100% isolation level to transformer from atmospheric moisture

b. Economical in long run

c. No operating cost

d. No maintenance cost

e. Actually extend the life of transformers which were originally designed for operation with conventional Silica-gel

breathers

f. All Trafotech transformers are equipped with in-built Sealed Breathing Device.

The system can be installed on any working transformer in the field, without altering the original design of transformer.

Experience shows that life of transformer extends by >10 yrs if it is operated dry i.e. at an overall moisture level of < 0.7% by

DWOI.

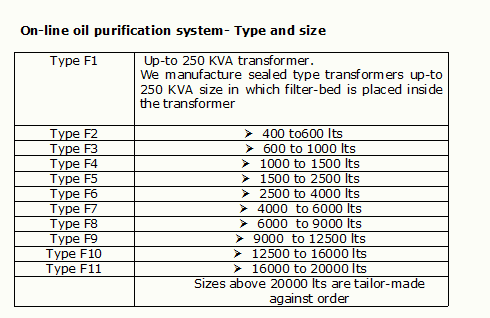

Benefits of On-line oil purifier system

a. It performs without taking shut-down on transformer.

b. It performs without consuming any electric power.

c. It can bring down moisture level of a wet transformer to below 15 PPM.

d. It can extract moisture from liquid (Oil) and solid insulation both.

e. In addition to moisture, it improves the specific resistance & Acidity value in oil.

f. It is provided with a micro-filter to remove solid impurities and a drain sump for removal of sludge periodically.

g. It is provided with anti-oxidant injection system.

h. It can easily be installed on old transformers of any make operating at site with-in 2 hours without any design

changes.

i. The moisture level in oil (in ppm) can be read on instrument installed on transformer.

ALL TRAFOTECH TRANSFORMERS ARE PROVIDED WITH THIS SYSTEM AS IN-BUILT FEATURE.